Carbon Data Analyst

“My mission is to embed a process by creating data templates, structure and monitoring systems that will allow us to check at any time, any period, for any project, what the company is accomplishing carbon wise. ”

Our new Carbon Guru, Cristian, has been making great headway in helping the company hit its 2023 sustainability goals.

Cristian Bain joined in May 2021 as a Document Controller. His degree in International Business Studies and meticulous nature soon saw him progress up the ladder to Estimator. Then, in July this year, his career trajected onto a new path when he accepted the Carbon Data Analyst role.

Hi Cristian, thanks for the interview. Can you tell me how you came about becoming ECL’s Carbon Data Analyst?

“I believe the company’s decision was down to the fact that I’m good at maths and Excel, and I get data. I know how to analyse and translate the data to make it useful for the business.

I’m also competent at embedding formulas in Excel, automating some of the data calculations, and creating tools to make the job much more accessible, more accurate, and less manual-intensive.”

I know it’s early days, but how are you finding the role so far?

“It is a challenge, which I like.

Gathering information in such minute detail that has never been done before is challenging, and it’s a long process but rewarding to watch the data grow.

From the perspective of setting up the department from scratch, putting in procedures, creating formats, tools and templates and automating the data is really rewarding.

We’re learning as we go along, and we’re currently implementing new procedures that will allow us to systemically collect valuable carbon usage data to accurately report, monitor and reduce our carbon footprint.

In 2021 and 2022, ECL spent a considerable amount of resources collecting our carbon usage data per annum. My mission is to embed a process by creating data templates, structure and monitoring systems that will allow us to check at any time, any period, for any project, what the company is accomplishing carbon-wise.“

That sounds like a huge undertaking.

“It is. It’s immense. For example, as a civil engineering company, we deal with aggregates. Aggregates mean a lot of things in terms of carbon usage. They come in many shapes and forms, and each variant has its own unique CO2 value. So it’s imperative we understand what material we’re working with and what impact it has in relation to CO2. In addition, each supplier, their locality and production method will also impact the product’s CO2 value, and all this data needs to be accessed and recorded.

Beyond aggregates, there are thousands and thousands of items/products that we need to evaluate to have a clear picture of each items carbon footprint. So the job is enormous but necessary.

By having this data accessible, we can make the right decisions to ensure the products we use are good for the job and have the lowest CO2 value.”

What are you currently head deep in?

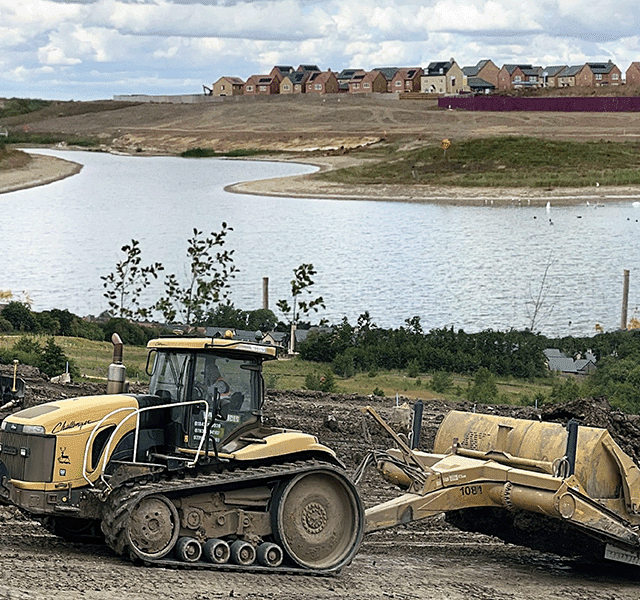

“Currently, we are reporting on some of our strategic residential development projects, providing CO2 reports related to each project. These reports show how much CO2 is embedded in the project and breaks down each section of the project and stage, such as roads, utilities, drainage and earthworks, so that carbon usage is visible.”

Has ECL achieved any significant milestones in reducing the company’s annual footprint this year?

“Yes, we have. HQ is now running on 100% renewable energy, and we’ve positively impacted the company’s fuel usage.

The switch from red to white diesel and the company’s investment in new plant machinery saw fuel savings.

Carbon savings have also been made by ensuring our sites have the latest plant equipped with fuel-saving technology, including both electric and hybrid engines, and by implementing micro-actions: sourcing from local suppliers, sourcing viable low CO2 products and incorporating solar generators, etc.

We’ve also recently agreed to use HVO fuel on an infrastructure project for Urban&Civic, which is a positive step forward in greener construction and will help reduce our scope one emissions for 2024.”

What’s the most challenging aspect of the job?

“As clients want more savings in CO2, it puts the responsibility on our suppliers to make their products more environmentally friendly. Influencing the mindset of our suppliers is a challenge. However, I believe as time passes and sustainability, which at the moment is still a new culture, becomes the norm, our suppliers, subcontractors and developers, everyone involved in this industry will be more conscious of their environmental impact, and CO2 itself will become more of a selling point.

The difficulty is changing the culture in the industry, but I like how the industry is heading and that ECL is at the forefront.”