Bridge infrastructure has multiple roles; they’re used to cross oceans and rivers, transport pedestrians and cars, and connect two parcels or lands or cities. Their size and shape will dictate their function and design advantages and disadvantages.

When choosing a bridge type for an infrastructure project, many factors exist, such as weight, volume, span required, location, resources, traffic volume, and budget.

Below are the five main bridge designs and information on the basic principles of each and how each design fit’s a specific function in our infrastructure.

Five main types of Bridges

- Beam Bridges

- Integral Beam Bridges

- Cantilever Bridges

- Arch Bridges

- Cable-Stayed Bridges

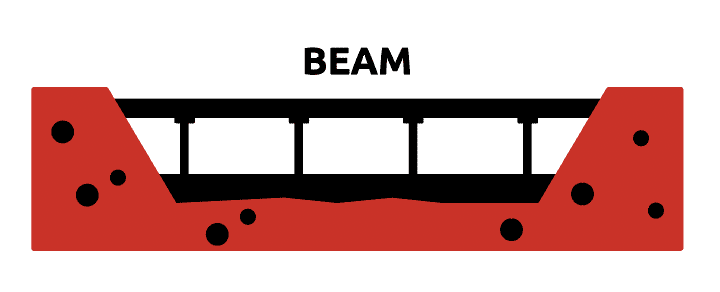

Beam Bridges

A beam bridge is one of the simplest and most cost-effective bridges to build. Beam bridges are the most popular type of bridge construction in the UK due to their simplicity in design.

A beam bridge may include several beams running in parallel to support the deck above, often referred to as a ‘simply supported’ structure, as there is no transfer of stress as seen in other types of bridge construction.

In its most basic form, all that is needed is a crossbeam long enough to cover the span and support from abutments under each end. Piers must be added to provide extra support for a longer continuous span. Doing this means you create a series of bridges joined together.

Beam Bridge Advantages

There are many advantages to beam bridges. They are quick and easy to construct, less costly than other bridges, and the roadway of a beam bridge can be easily maintained and repaired.

- Beam bridges are quick and simple to construct.

- Beam bridges can be constructed in various materials, such as wood, concrete, and steel, making them extremely versatile.

- The beam bridge design can be adapted to support multiple lanes of traffic, sidewalks, and railings.

- The effects of thermal expansion and movements of the ground are easily sustained.

- Bridge modules can be prefabricated.

- A beam can be engineered into place with the least disruption to traffic.

- The roadway of a beam bridge can be easily maintained and repaired.

Beam Bridge Disadvantages

- Limited span length between supporting structures.

- Large vessels or vehicles cannot pass underneath.

- Not suitable for very heavy loads or wide loads.

- Not suitable for high-speed traffic.

- They can start to sag as they age.

- Poor aesthetics.

- Costs will fluctuate alongside steel prices.

- Maintenance is expensive – painting steel bridges is expensive and time-consuming.

Integral Beam Bridges

Integral beam bridges are a modern design approach to the traditional beam bridges that incorporate bridge bearings and expansion joints. The developments in construction methods and prefabricated beam design have enabled the removal of maintenance issues surrounding bridge bearings and expansion joints.

The substructure and superstructure of an integral bridge beam are constructed without any joints between spans or between spans and abutments. Therefore, the superstructure and abutments act as single structural units that work well for short to medium span bridges.

Integral Beam Bridge Advantages

- Compared to conventional bridges, an integral beam bridge’s construction and maintenance costs are much lower.

- Integral beam bridges are simple and rapid to construct.

- If an integral bridge is constructed in place of an existing bridge, the existing foundations can be.

- Bridge modules can be prefabricated.

- A beam can be engineered into place with the least disruption to traffic.

- Eliminating water leakage on critical structural elements can be done by implementing a drainage layer behind the integral abutments.

- Due to the elimination of bearings and expansion joints, there are less tolerance restrictions.

- The vehicle riding quality on an integral beam bridge is smoother since no expansion joints exist.

- The roadway can be easily maintained and repaired.

Integral Beam Bridge Disadvantages

- Integral bridges are unsuitable in zones with a chance of expansion/contraction of more than 51mm during temperature variations.

- They are not preferred when subsoil or embankments are of poor strength.

- The geometry of the bridge and the material used for the construction play a key role in the case of integral bridges. They are responsible for the displacement affects on the bridge.

- There is a chance of the formation of plastic hinges in piles due to high stresses of expansion and contractions resulting in the reduction of the axial load capacity of piles. The foundation should be designed considering this point.

- Integral abutments are suitable for bridges up to the length of 40 m for steel girder bridges and 50 m for concrete girder bridges.

Take a look at ECL’s recently constructed Integral beam bridge.

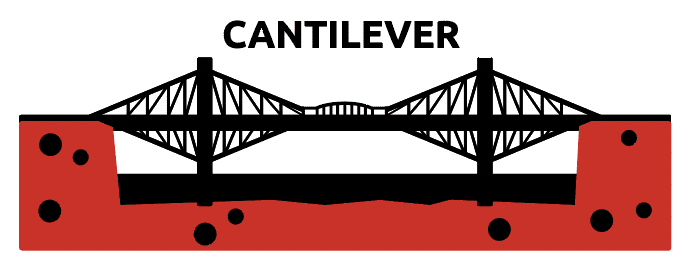

Cantilever Bridges

A cantilever bridge is built using cantilevers, structures that project horizontally and are supported on one end only. If you’re not familiar with the cantilever principle, picture a diving board supported at one end.

A cantilever bridge is built using pillars securely anchored to the ground. The structure is constructed outwards from each pillar, with the horizontal beam often supported using diagonal bracing.

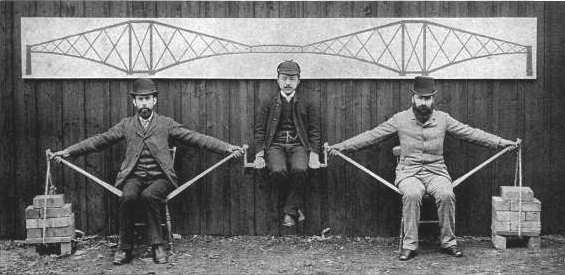

The famous picture below shows The Forth Railway Bridge engineers John Fowler, Benjamin Baker and Kaichi Watanabe demonstrating the cantilever principle.

In the photo, Watanabe conveys the load on the suspended central span, Fowler and Baker the cantilevers, and the bricks on either the anchor for the cantilever beams.

These bridges can be made using different materials, such as box girders, structural steel, or prestressed concrete for larger bridges carrying road or rail traffic.

This type of bridge can be used for pedestrians, trains, and motor vehicles. Cantilevers are especially useful for spanning a waterway without dividing it with river piers; the benefits are:-

- The river channel remains unblocked.

- Boat traffic can travel under the bridge.

- Reduces the risk of bridge failure in a flood situation.

Cantilever Bridge Advantages

- Cantilever bridge design is an ideal method for creating long spans.

- Most suitable for flood-prone areas and deep rocky valleys, where falsework might be dangerous or difficult.

- Support is required only on one side of each cantilever.

- The bridge floor is formed into sections, preserving uniformity and quality.

- Multiple cantilever spans can be constructed simultaneously from all its columns.

- Navigation or passage under the bridge is not disturbed during the construction process.

- Suitable for deep rocky valleys and flood-prone areas where supporting structures cannot be built.

- Cantilever bridges can withstand the effects of thermal expansion and floor speed more than other types of bridges.

- The lack of supporting piers in cantilever bridges provides extra flexibility to the styles and geometry of the highway supported by the bridge.

Cantilever Bridge Disadvantages

- Challenging to construct and maintain.

- Advanced analysis is needed to prevent bridge failure.

- Considerable material costs as these bridges require a heavy structure to manage stability.

- A high level of tension is experienced during construction, known as negative moments.

- Stability relies on balancing compressive and tensile forces.

- Not suitable for extreme climate conditions or earthquake-prone areas.

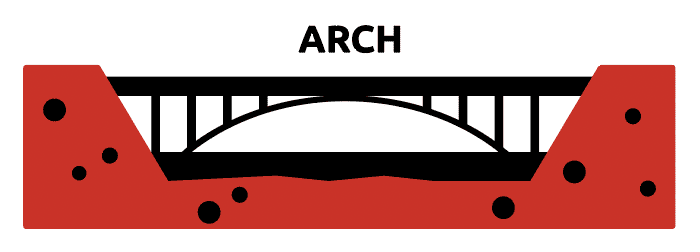

Arch Bridge

Arch bridges are incredibly strong and straightforward bridges that have been used for thousands of years.

These bridges were introduced by the Romans and are still popular today; however, in this modern time, arch bridges are constructed from concrete rather than the stone and brick material used historically.

The construction of an arch bridge sees abutments at each end shaped as a curved arch. Its semi-circular structure works by transferring the weight of the bridge and its loads onto the two abutments. The natural curve of the arch and its ability to disperse the force outward significantly decreases the effects of tension on the underside of the arch.

These bridges are used for anything from pedestrians to heavy rail bridges. The negative to this type of bridge construction is the small spans and slow construction process.

Arch Bridges Advantages

- There are multiple design options (one, two or three arches)

- Arch bridges can be constructed from a variety of building materials.

- They can also be constructed to move in inverse ways to represent temperature changes.

- Arch bridges can facilitate a greater span compared to beam bridges but less span than cantilever and suspension types).

- Maintenance costs are reduced as these bridges have fewer distortions.

- Arch bridges can provide excellent stability and a solid deck to withstand high-volume vehicle traffic.

Arch Bridge Disadvantages

- Time-consuming to construct and maintain.

- Creating a long span length requires more arches.

- They can be more costly to construct as they require more material than the beam or cable bridge.

- Requires strong side support to complete a successful span.

- Requires substantial expertise to build.

- The arch must be perfect for the bridge design to be adequate.

Cable-stayed Bridge

The cable-stayed bridge remains a popular design for spans greater than those of cantilever bridges and shorter than the longest suspension bridges, with it’s design dating back to the 16th century.

A cable-stayed bridge construction is dependent upon towers/pylons, which are the load-bearing element of the structure. Cables are connected from the pylons to the deck below. Either directly from the top of the tower or at different points of the column. Most people associate this feature with cable-stayed bridges. This type of bridge structure is used for larger spans that can’t be achieved with a cantilever bridge design but less than a suspension bridge. One of the main issues with this type of bridge is that the central connection of the cables can place horizontal force on the deck. Because of this, the deck structure has to be reinforced to withstand ongoing forces.

The build materials most commonly used in cable-stayed bridges are concrete or steel pylons, post-tensioned concrete box girders, and steel rope.

Advantages of Cable-Stayed Bridges

- Significantly less time to build compared to other bridge types. (Fewer anchorages are needed than other bridge designs, and the deck can be supported with fewer suspension cables.)

- Robust bridge design which can handle more pressure and resist environmental conditions such as earthquakes.

- Cost-effective.

- Multiple design options: (cantilever-spar, multiple-span, side-spar and cradle-system designs).

Cable Stayed Bridge Disadvantages

- Suitable for short to medium distances (The maximum recommended length is just 1,000 meters).

- Difficult to access in some areas, which means higher-than-average costs of Maintenance.

- Cables can be prone to corrosion and high levels of fatigue.

- Easier to vandalize (by cutting cables).

- Not suitable in climate conditions prone to severe wind events.

If you have any questions or queries, a member of staff will always be happy to help, please feel free to get in touch, and we will get back to you as soon as possible.